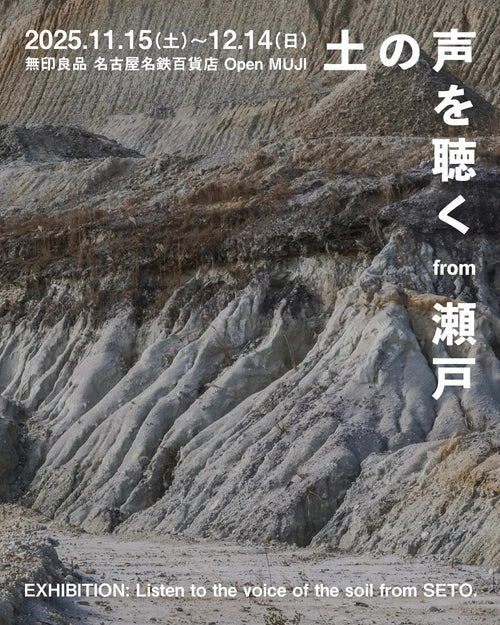

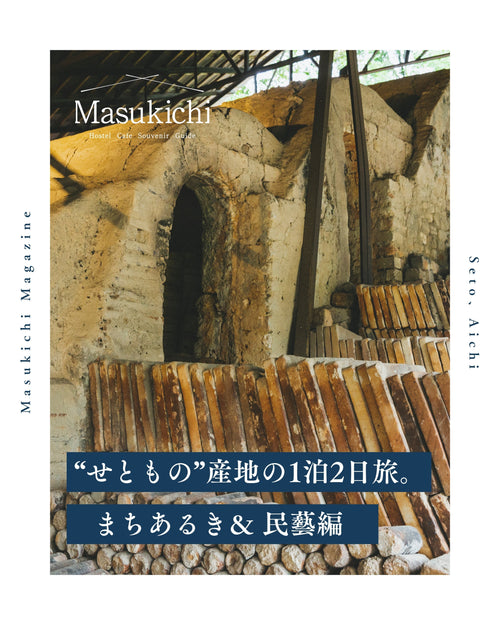

Seto City in Aichi Prefecture is a pottery production center with a history of over 1,000 years.

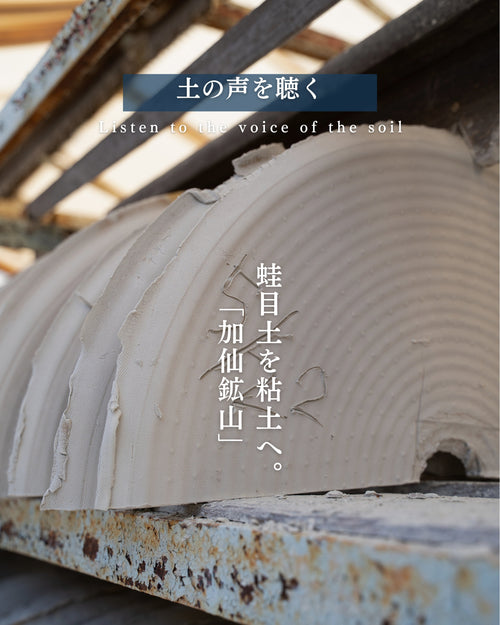

The reason for this is that the best clay for pottery, called "Gairome," can be extracted here.

Why is frog eye suitable for pottery?

Its main feature is its plasticity, which allows it to retain its shape like a shape-memory alloy, making it very easy to throw on a potter's wheel. It turns pure white when fired and is highly fire-resistant . If it is refined and the clay content is mixed with feldspar and silica, it can even be used to make porcelain clay.

It is truly a clay that was born for pottery. Thanks to this clay, pottery has been produced in Seto for over a thousand years. However, frogeye is a natural resource that is dug from the mountains, and as it is dug up, it disappears.

I would like more people to know about this.

We spoke to people involved in the ceramic raw materials industry and potteries who work with clay in Seto.

*If you would like to know more about frog eyes, please click here .

*

In the previous series, we have been talking about "soil," but Seto is also the city in Japan that ships the most silica sand, the raw material for glass.

What's more, it comes from the same mine where frog eyes are mined.

We spoke with Maki Kosuke, the fifth generation executive director of Jinya Marusen Ceramic Materials, a company that has been in business since 1950 and sells mainly silica sand but also clay.

Seto City is the number one city in Japan for shipping silica sand, a raw material for glass.

Silica sand stockyard. (Photo: Jinya Marusen Ceramic Raw Materials)

Silica sand is the raw material for pottery clay and glass.

Let me start by introducing them. In fact, both of these are natural resources that were originally created from magma.

Basically, like soil, it is created by the weathering and decomposition of granite, a rock formed when magma slowly cools and solidifies underground . In the case of silica sand, it is made up of grains that are rich in the mineral quartz (and some feldspar).

Silica sand melts when fired at high temperatures.

By melting and changing shape, it is used to create products that are familiar to us, such as window glass and the liquid crystal display glass used in electronic devices.

This silica sand is actually abundant in Seto, accounting for about 70% of the domestic shipments.

What is "Jinya Marusen Ceramic Raw Materials"?

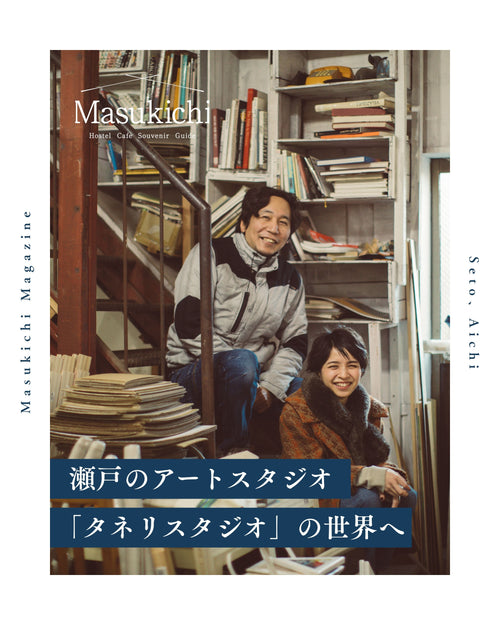

Mr. Maki Kosuke, Managing Director of Jinya Marusen Ceramic Materials (you can read Mr. Maki's story here ).

Mr. Maki Kosuke, Managing Director of Jinya Marusen Ceramic Materials (you can read Mr. Maki's story here ).

Now, we visited Jinya Marusen Ceramic Materials, which sells products made from silica sand, which is commonly found in Seto.

It is about 1.3 km from Owari Seto Station on the Meitetsu Seto Line, and is easily accessible even on foot.

Its history dates back to the Meiji period, when the ancestor, Sentaro Maki, moved from Nagoya to Seto and started a diversified ceramics-related business, including kiln firing to make ceramics and clay manufacturing.

We started out as "Jinya Marusen Ceramic Materials" shortly after the war, and have continued to operate as a company dealing in ceramic materials ever since.

"We are a manufacturer of ceramic raw materials, mainly producing silica sand, clay for tiles, and gravel, which is a by-product. In Seto, there are two large associations that mine raw materials: the Aichi Prefecture Ceramic Industry Cooperative Association and the Aichi Prefecture Silica Sand Mining Cooperative Association , and we purchase our raw materials from them."

especially, In Kosuke's case, he wants raw sand that contains a lot of silica sand, so he purchases it from the Aichi Prefecture Silica Sand Mining Cooperative .

Visible from the site A mine owned by the Aichi Prefecture Silica Sand Mining Cooperative . (Photo: Jinya Marusen Ceramic Raw Materials )

The Aichi Prefecture Ceramic Industry Cooperative Association mines clay such as frogeye. On the other hand, the Aichi Prefecture Silica Sand Mining Cooperative Association wants silica sand. However, each mountain is not neatly divided into clay and silica sand.

"Even on the same mountain, the things you can extract vary depending on the stratum. Above the frog-eye clay, there is always a gravel layer made up of sand, pebbles, and mud carried by rivers and waves , and within that lies silica sand. By the way, above that is gravel."

Although each association wants different things, as a result, depending on the layer they are digging at the time, they will find what each other wants. Once they find it, each association will sell it. In this way, china clay and silica sand are mined side by side.

What is the sand (quartz sand) in the product?

These are the sand products (quartz sand).

Jinya Marusen Ceramic Materials carries nearly 10 different sizes of silica sand, including the ones mentioned above. Can you see the different particle sizes? Each of these is made into a product and sold.

Depending on the size, they can be used for a variety of purposes, such as being used as a raw material for glass or as sand for golf bunkers.

Separating particles by size and turning them into products

Inside the factory. After mixing the raw sand with water, the particles are separated by size using a bucket conveyor.

When the raw sand is dug, it contains silica sand of various sizes and even clay mixed in. Therefore, at the factory, bucket conveyors with different hole sizes are used to separate the sand.

Clay is also a by-product that is produced during the process of extracting silica sand from raw soil.

They are squeezed into clay and sold as industrial clay for use in building tiles, toilet bowls, and other products.

This is also a valuable "frog-eye" clay, but clay extracted from a layer with a high silica sand content has poor shape retention, so it is not suitable for tableware.

This is dried "frog-eye clay" that comes out during the elutriation process.

Dried frog eye clay is used inside car tires and is also used as an ingredient in cosmetics.

Thoughts on frog-eye clay

Kosuke has a strong passion for clay. He launched the CONERU nendo shop & space , which aims to bring pottery closer to people, and is also involved in activities such as hosting mine tours together with Mr. Kato, the president of Kasen Mine , which we introduced previously.

"The frogeye clay mined in Seto is also widely used in other pottery-producing areas. Because it is a natural resource, it will disappear. If clay could no longer be mined in Seto in the future, it would have a grave impact on the ceramic culture of Japan as a whole.

However, in Seto, there has been absolutely no discussion with a sense of crisis about the depletion of resources. It's already happening in neighboring Mino. Isn't it Seto that needs to take the initiative in thinking about and discussing the issue? That's what led me to start CONERU .

However, there's no point in being too serious about it, so I think it would be good to start by opening a shop where people can casually get in touch with clay, and then hopefully some discussion will start from there."

The frog's eye and silica sand produced in the mines of this area continue to support our lives and culture, changing in various forms.

We want to listen to the voice of the soil and silica sand so that these things do not quietly disappear.

[Listening to the Voice of the Soil: Introduction to the Series]

Part 1: From raw soil to clay. [Listening to the voice of the soil. Column on the Kasen Mine]

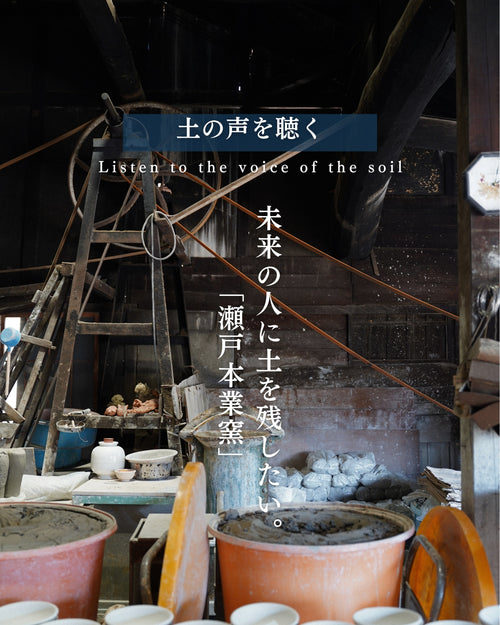

Part 2: "I want to leave the soil for future generations" [Listening to the voice of the soil: Column on Seto Hongyo Kiln]

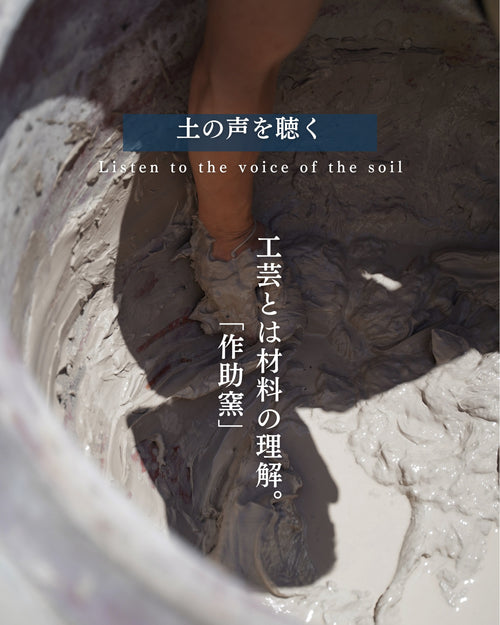

Part 3: Craftsmanship is about understanding materials. [Listening to the voice of the clay. "Sakusuke Kiln" column]

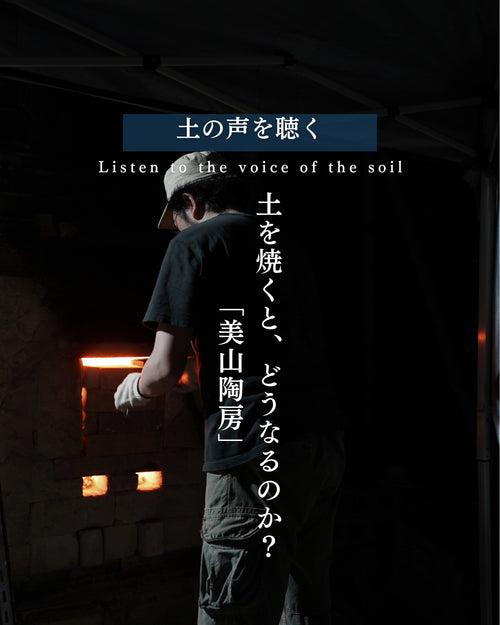

Part 4: What happens when you bake clay? [Listening to the voice of the clay. Column by Miyama Pottery Studio]

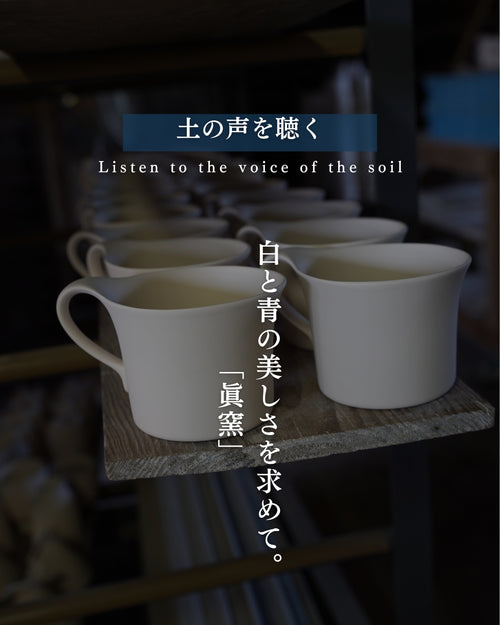

Part 5: In search of the beauty of white and blue. [Listening to the voice of the soil: Shin Kiln Column]

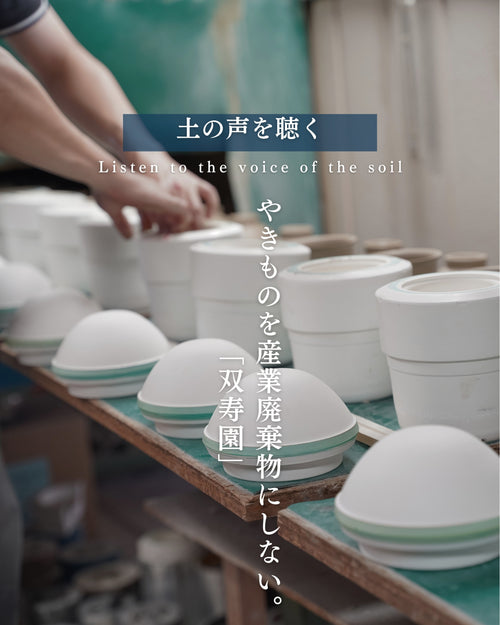

Part 6: Don't turn it into industrial waste. Think about recycling soil. [Listen to the voice of the soil. "Soujuen" column]

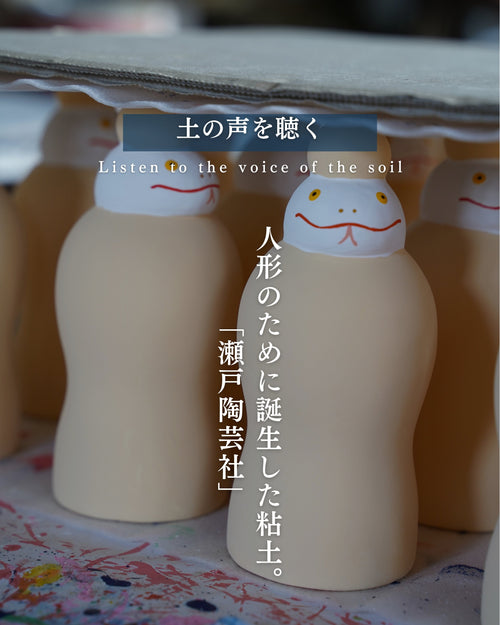

Part 7: What kind of clay is used in ceramic dolls? [Listening to the voice of the soil. Column compiled by Seto Tougeisha]

Part 8: Are the raw materials for pottery and glass harvested from the same mountain? [Listening to the voice of the soil: A column from "Jinya Marusen Ceramic Raw Materials"]

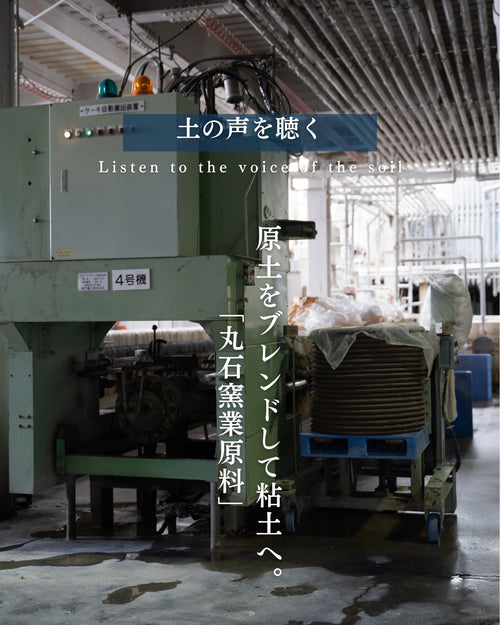

Part 9: Clay making by a long-established clay company founded about 150 years ago [Listening to the voice of the soil. Column on "Maruishi Ceramic Raw Materials"]